by ruijie

Laser operating temperature requirements

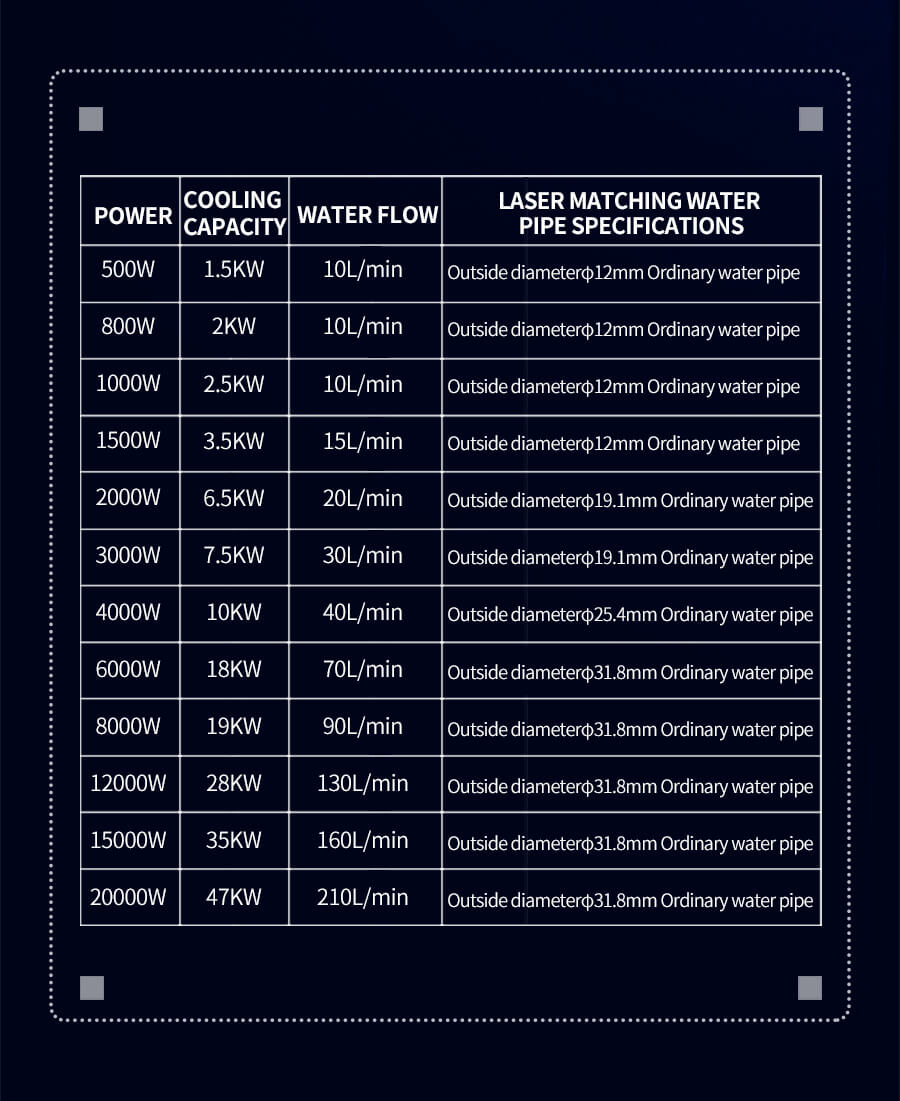

The working environment temperature of the laser should be controlled at about 22 degrees. The low temperature water temperature of the water cooler is set at 20-24 degrees, and the high temperature water temperature is set at 28-30 degrees. The water cooler needs to work for more than 20 minutes before the laser emits light. Ensure that the actual temperature of the water cooler reaches the set temperature. Open the monitoring software and confirm that the temperature of the laser main control board and the module optical sensor are both above 18 degrees to meet the light emission conditions.

If the set temperature is not reached, the monitoring interface will pop up an alarm page to prohibit the mountain from emitting light.

To resume work, restart the laser and observe that the temperature of the monitoring interface reaches 18 degrees before emitting light.

Antifreeze Basic principles

Cooling water has a "freezing point". When the cooling water temperature is lower than the "freezing point", the volume expansion of the cooling water when it solidifies will cause the flow-through components in the laser cooling system, such as the cold water plate, water distributor and other components to expand and deform, resulting in cracks and damage to the optical devices, causing the laser to be returned to the factory for repair. Therefore, winter antifreeze protection measures for the laser must be taken to ensure the normal operation of the equipment.

Antifreeze solution

1, Keep the chiller running

If there is no power outage in the local area, the chiller can be kept running, and both the low-temperature water and the normal temperature water can be set to around 5°C (to ensure that the cooling water is above the freezing point and save electricity)

2, Drain the cooling water in the machine

Drain the cooling water in the laser and water chiller after each use.

Drainage method:

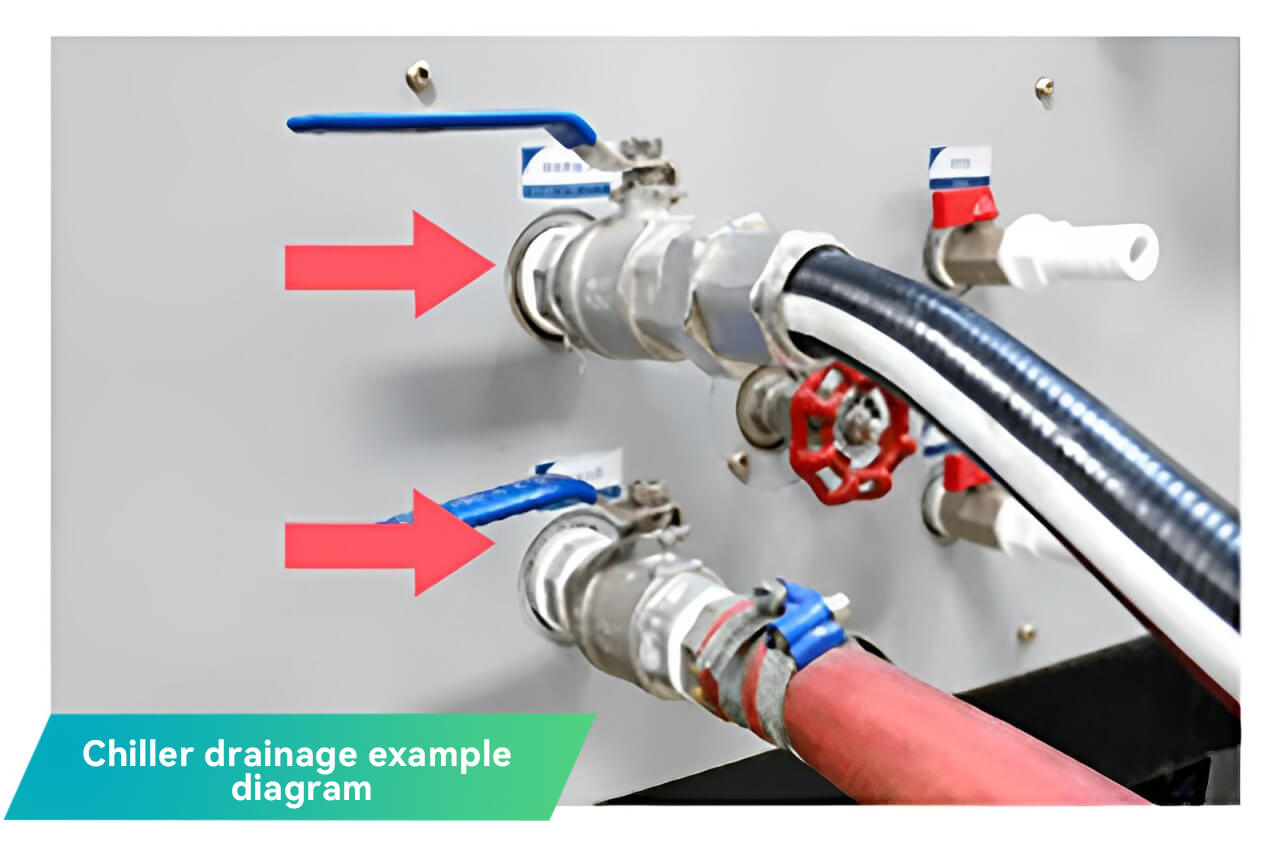

Remove the water inlet pipe from the chiller, and then use compressed gas to ventilate the water inlet (WATER IN) until the remaining water in the chiller is blown out.

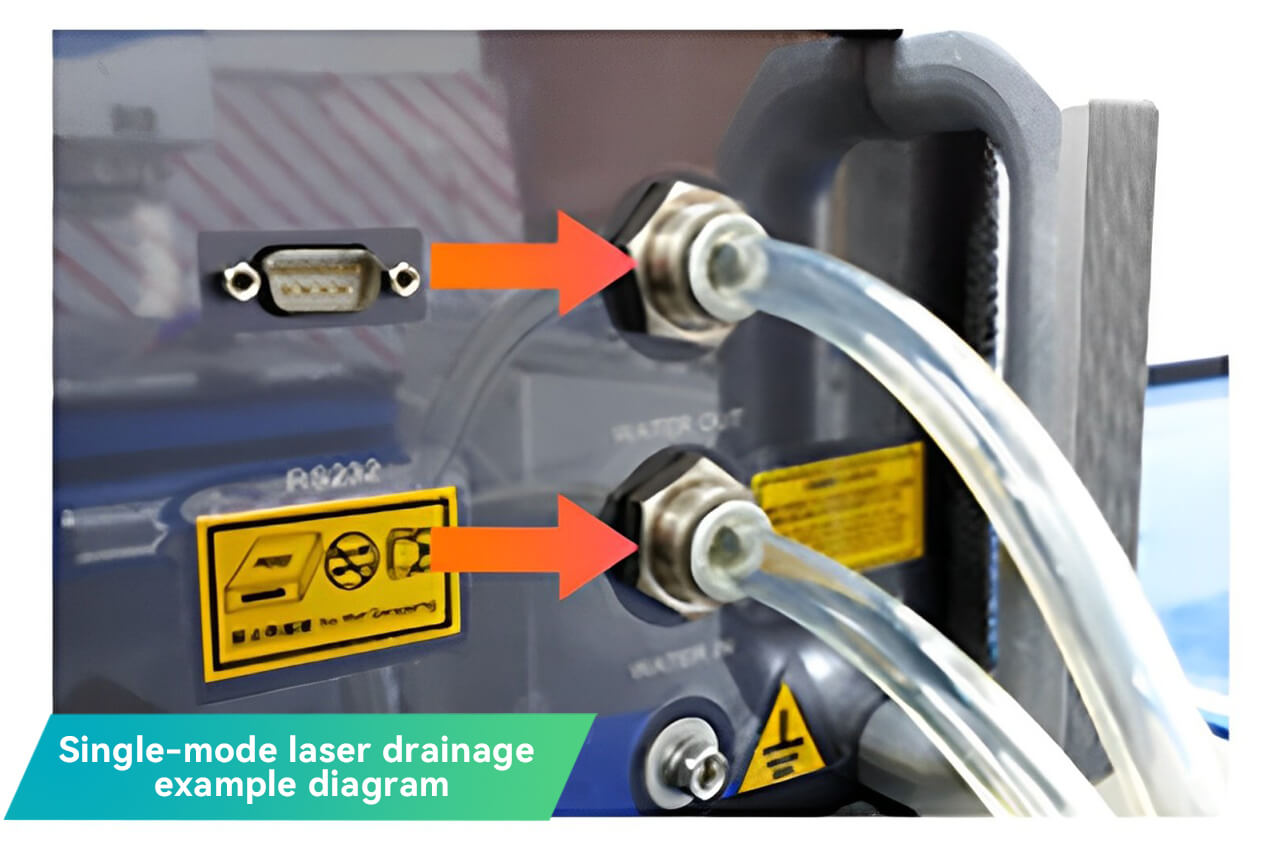

Remove the water pipe of the water inlet from the laser, and then ventilate the water inlet (WATER IN) with compressed gas until the residual water in the water cooling pipe inside the laser is blown out from the water outlet.

Remove the water pipe of the water inlet from the laser and then ventilate the water inlet (WATERIN) with compressed gas until the residual water in the water cooling pipe inside the laser is blown out from the water outlet. Then plug the water inlet and outlet with a water pipe (or rubber plug) to prevent dust from entering the water pipe.

3, Use antifreeze to replace cooling water

When the operating environment is often out of power and does not have the conditions to drain the cooling water every day, antifreeze must be used.

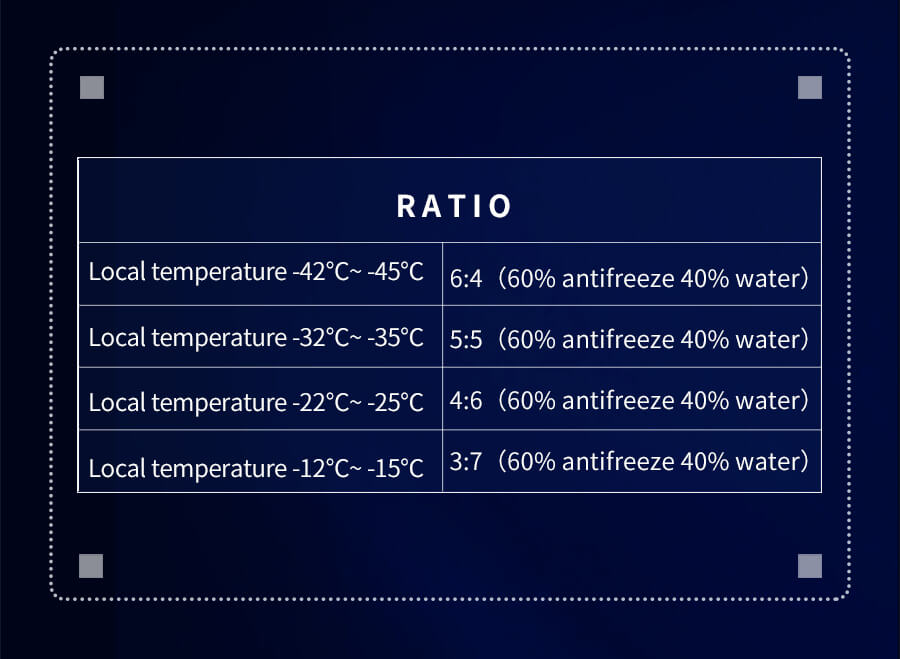

Please choose antifreeze with appropriate freezing point according to the local temperature. The antifreeze is not the lower the freezing point, the better. Instead, choose antifreeze slightly lower than the local minimum temperature.

Example: Max Laser recommends the American Clariant brand as the antifreeze for water-cooling machines

Notice!

No antifreeze can completely replace deionized water, and it is not recommended to use it for a long time all year round. After winter, it is recommended to use deionized water or distilled water to clean the pipes and resume using deionized water or distilled water as a coolant. If the equipment is shut down for a long time (such as during the Spring Festival) or before the laser is transported, the cooling water in the equipment must be drained and compressed air must be used to blow away the residual water in the equipment (including the laser and chiller) to prevent internal ice from damaging the device.

If you have any questions, you can also call the customer service hotline at any time

400-001-9366 After resale, or Whatsapp +8613646402382 our staff

will provide you with relevant technical answers